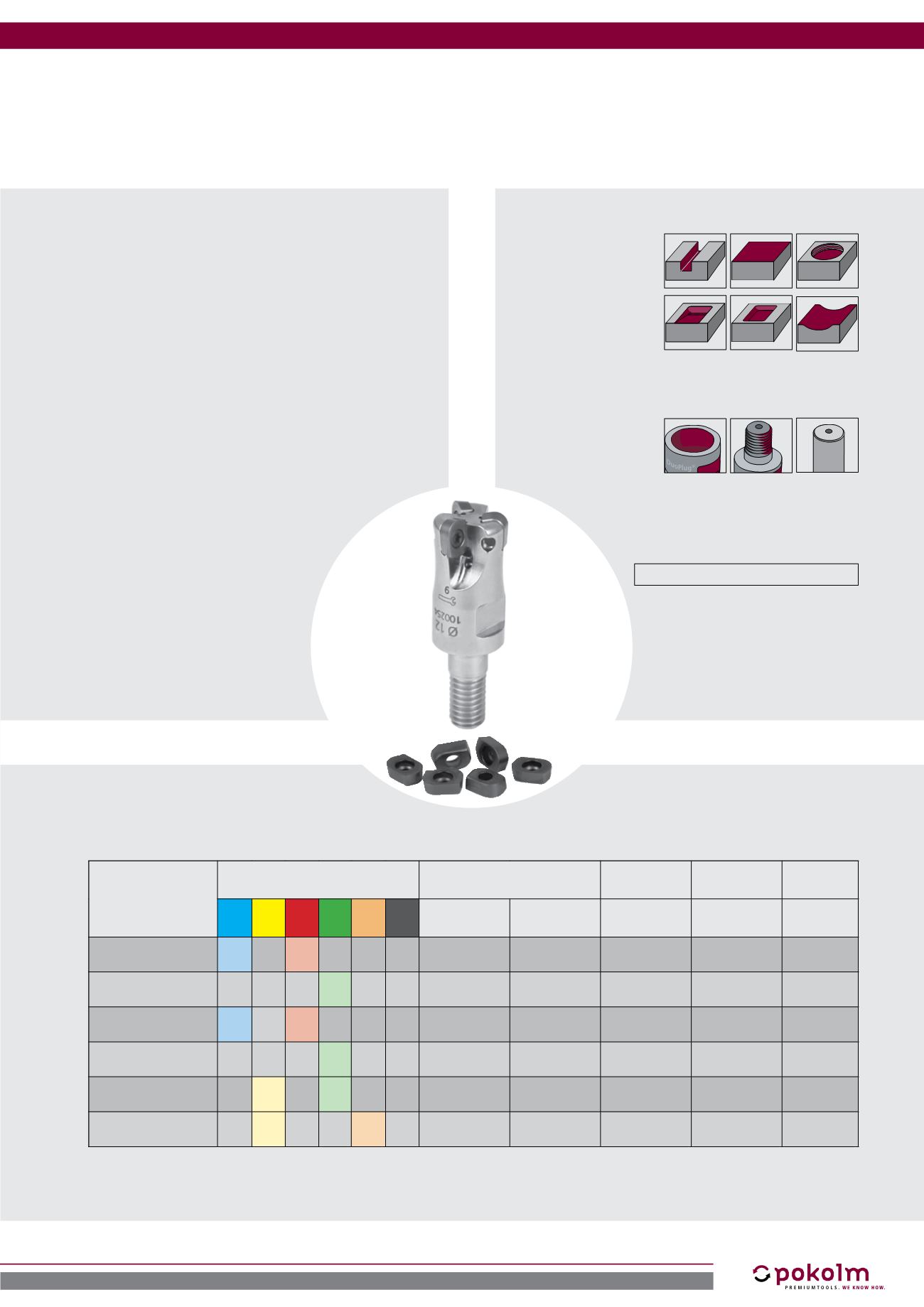

P M

K

N S

H

HSC 05 PVTi

- - -

0,05 - 0,7

0,05 - 0,4

6,2

2,2

2

HSC 05 PVDiaN

- - - - -

0,05 - 0,7

0,05 - 0,4

6,2

2,2

2

HSC 05 PVTiH

- - -

0,05 - 0,7

0,05 - 0,4

6,2

2,2

2

K10 Poliert

- - - - -

0,05 - 0,7

0,05 - 1,0

6,2

2,2

2

K10 PVTi

- - - -

0,02 - 1,0

0,02 - 1,0

6,2

2,2

2

M40 PVST

- - - -

0,03 - 0,6

0,05 - 1,0

6,2

2,2

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

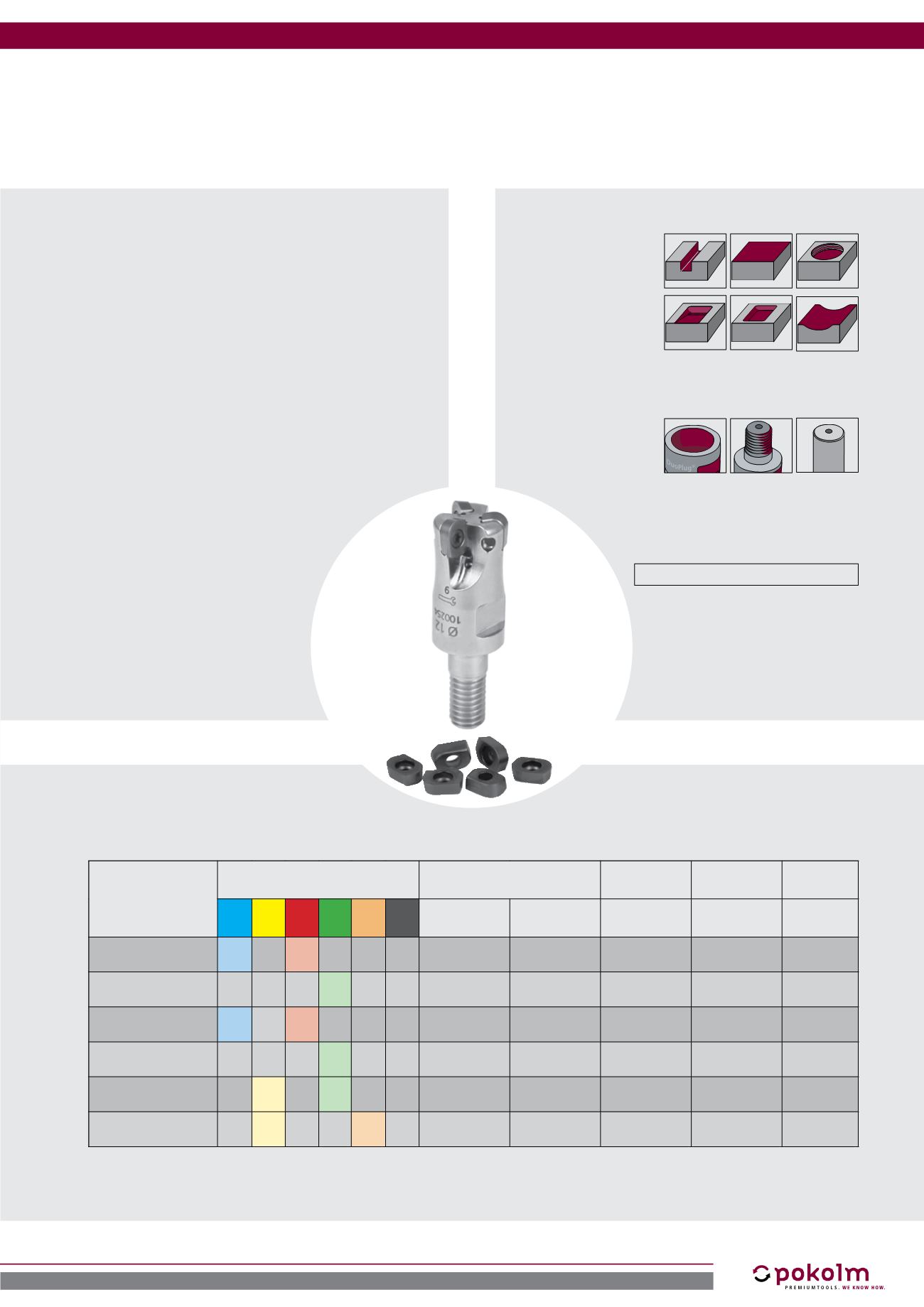

Machining types

Connection types

Properties

Cutting materials

Sizes

Page

SLOTWORX

®

HP

HIGH FEED RATE CUTTERS

High performance chip removal rates in hard machining

S: diam. 10 - 32 mm 192

uu

One insert carbide grade for soft and hard

machining

uu

Real corner radius for true to contour machining

uu

High-precision ground indexable inserts

uu

Maximum cutter body stability due to

negative axial angle

uu

High number of teeth on smallest tool diameter

uu

Can replace solid carbide tools in some areas

thickness

ISO standard

feed per tooth | d.o.c.

a

p

(mm)

f

z

(mm)

length

l (mm)

s (mm)

radius

r

p

(mm)

Carbide grade | Coating

191