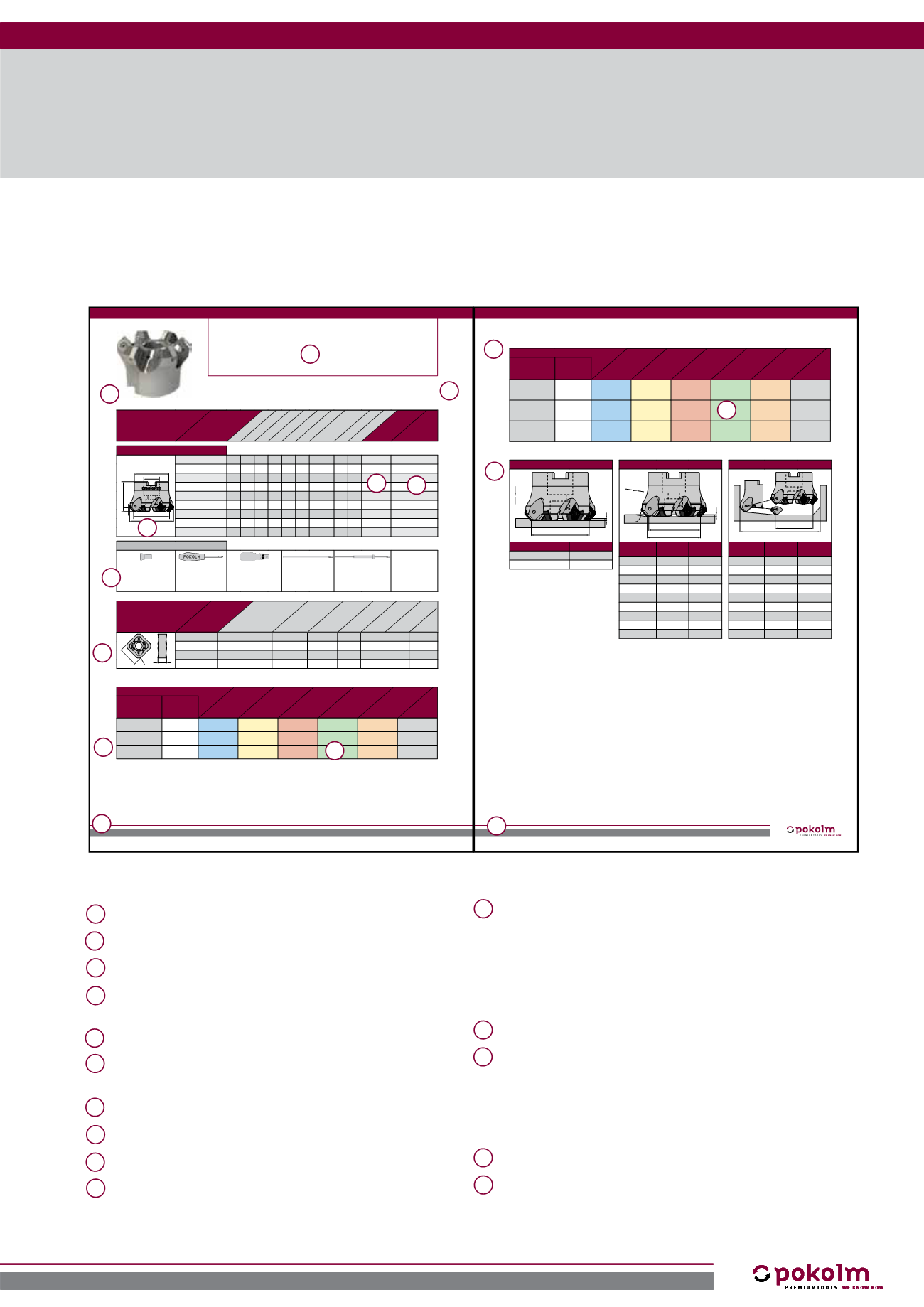

Name of the product series

Description of the product series

Example photo of a product in the product range

Dimensioned sketches of each type of connection,

corresponding dimensions given in the adjacent table

Accessory allocation; for accessories see section 7

List of accessories with page reference

Properties, symbols in the key and

on the last page of the catalogue

Suitable indexable inserts

Feed per tooth (fz) and d.o.c. - depth of cut (ap)

ATTENTION! The values given are merely guide values and

must be checked for each individual case!

High a

p

values may not be combined with high f

z

values!

Therefore, in case of high a

p

values, low f

z

values must

be used and in case of high f

z

values, low a

p

values

must be used.

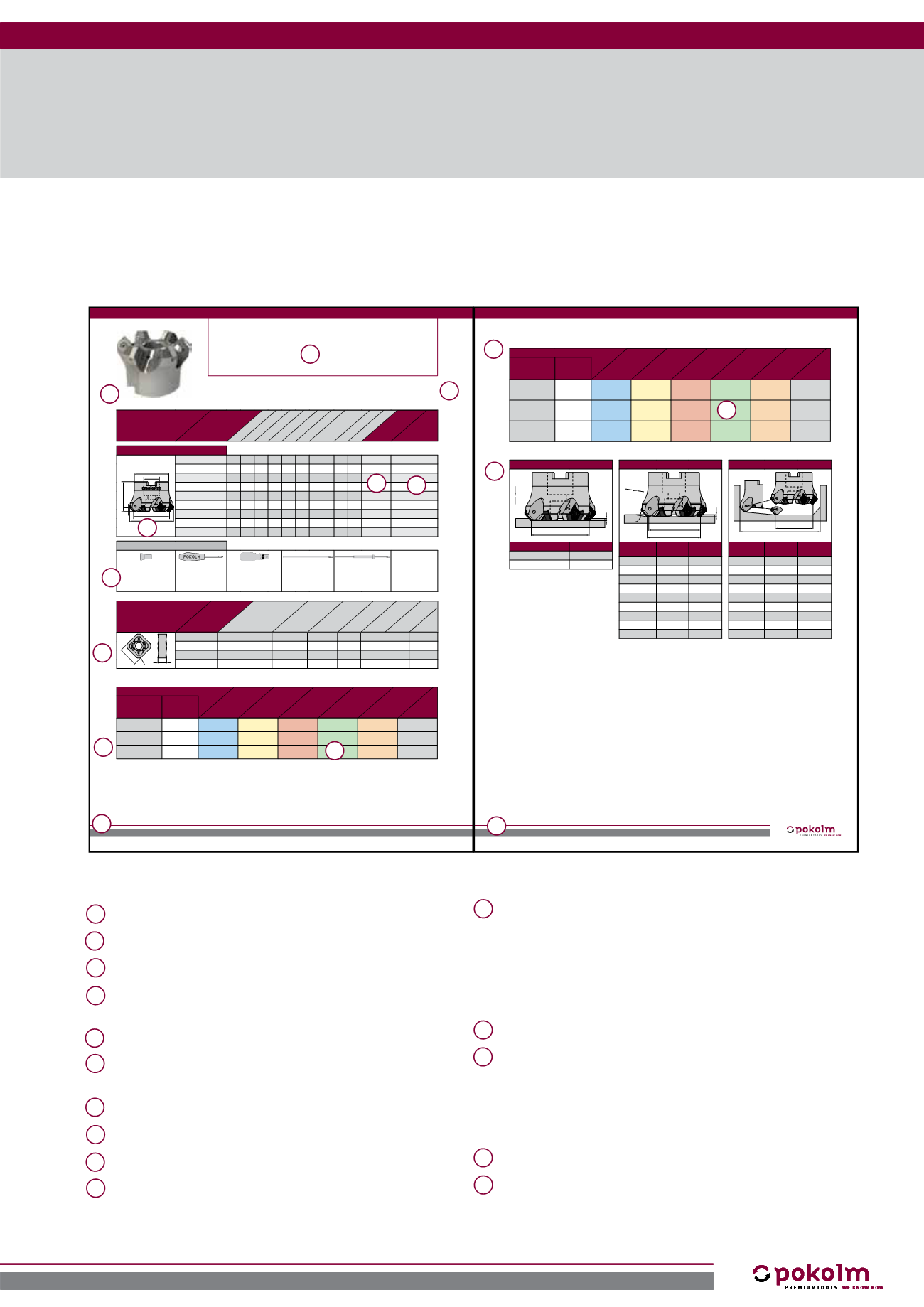

Cutting speed

The values given reflect the bandwidth for both roughing

and finishing. The

bold

figure in the middle is the respec-

tive average value.

If the figures are in

italics

, they are merely given as values

for minor applications!

Extended operation data

Key to the pictograms in the tables and to the main and

secondary precision, medium and rough machining app-

lications

T

he product pages contain information needed for purchasing and for use of the respective cutting system. Time-consuming

paging and searching for accessories and cutting data is no longer necessary - saving you valuable time!

Key: stock statuses

28

latest items!

available as long as stock lasts

on request

stock item, subject to confirmation

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Feedper

tooth|d.o.c.

P40 PVSR

f

z

(mm)

a

p

(mm)

0,08-0,55

0,1-6

-

-

-

-

-

K10 PVTi

f

z

(mm)

a

p

(mm)

-

-

0,1-0,55

0,1-6

-

-

-

M40 PVST

f

z

(mm)

a

p

(mm)

-

0,08-0,3

0,1-4

-

-

0,08-0,2

0,1-3

-

PLANWORX®

diam 40 - 250 mm

Indexable inserts

Catalogueno.

DIN Specification

CarbideGrade

Coating

l

s

r

M

S

r

l

0531842 SNMX 135408 ER

P40

PVSR

13

5.4

0.8

M 4.0

0531862 SNMX 135408 ER

K10

PVTi

13

5.4

0.8

M 4.0

0531896 SNMX 135408 ER

M40

PVST

13

5.4

0.8

M 4.0

Milling cutterbodies

Catalogueno.

Accessories

Features

d

1

l

r

l

3

l

2

l

1

d

2

d

3

z

Shell typemilling cutterbodies

d

d

1

l

2

l

3

d

3

d

2

440331 40 13 0.8 42 6.7 -

diam. 22 40 4 A, B,C,D, E

550331 50 13 0.8 52 6.7 -

diam. 27 48 5 A, B,C,D, E

663331 63 13 0.8 52 6.7 -

diam. 27 60 6 A, B,C,D, E

880331 80 13 0.8 52 6.7 -

diam. 32 70 8 A, B,C,D, E

10100331 100 13 0.8 52 6.7 -

diam. 40 90 10 A, B,C,D, E

12125331 125 13 0.8 52 6.7 -

diam. 40 90 12 A, B,C,D, E

14160331 160 13 0.8 52 6.7 -

diam. 40 120 14 A, B,C,D, E

16200331 200 13 0.8 52 6.7 -

diam. 60 160 16 A, B,C,D, E

20250331 250 13 0.8 52 6.7 -

diam. 60 160 20 A, B,C,D, E

Accessories

40 505 P

Torx screw

A > Page 195

15 500 P

Torx-screwdriver (Tor-

x-Plus)

B > Page 196

TV 2-8

Screwdriver torque

Vario®-Swithwindow

scale, +C > Page 197

T15 500 P

Torx interchangeable bit

for Torque Vario®

D > Page 197

T15 502 P

TorxMagicSpring compati-

ble bit f. Torque Vario®

E > Page 198

Face-milling cutter with maximum chipping depth of 6 mm, negative axial rake angle

for square inserts with eight cutting edges. Internal coolant supply up to tool diameter

125mm. Differential pitch for smooth running.

Feed per tooth (fz) | d.o.c. (ap)

PlaNworx® FacemIllINgcutterS

28

29

major application

minor application

roughing

pre-finishing

finishing

Material

steel

stainless steel

cast iron

non-ferrous

materials

high-temperature

alloys

hardened steel

Quality

Coating

Application

P40 PVSR

roughing

pre finishing

finishing

100

200

300

100

200

300

-

-

-

-

-

-

K10 PVTi

roughing

pre finishing

finishing

-

-

150

175

200

150

175

200

150

200

250

-

-

-

M40 PVST

roughing

pre finishing

finishing

-

80

130

180

100

155

210

120

185

250

-

-

30

55

80

40

65

90

60

90

120

-

Extended operation data

Cutting speed (Vc in m/min)

Ramping

Y

X

α

d

1

Cutterdiam.

d1

α

°

y

40

<11

29.5

50

<8

39.5

63

<6,5

52.5

80

<4

69.5

100

<3,5

89.5

125

<2,5

114.5

160

-

-

200

-

-

250

-

-

Helix

Dminmax

d

1

Cutterdiam.

d1

D

min

D

max

40

89.5

93.5

50

109.5

113.5

63

135.5

139.5

80

169.5

173.5

100

209.5

213.5

125

259.5

263.5

160

-

-

200

-

-

250

-

-

Plunging

X

d

1

Cutterdiam.d1

X

max

40-125

4

160-250

-

5

7

2

6

1

3

12

13

11

10

8

9

14

4

15

5

Catalogue system

12

13

14

11

10

8

5

7

2

6

1

3

9

4

15