75

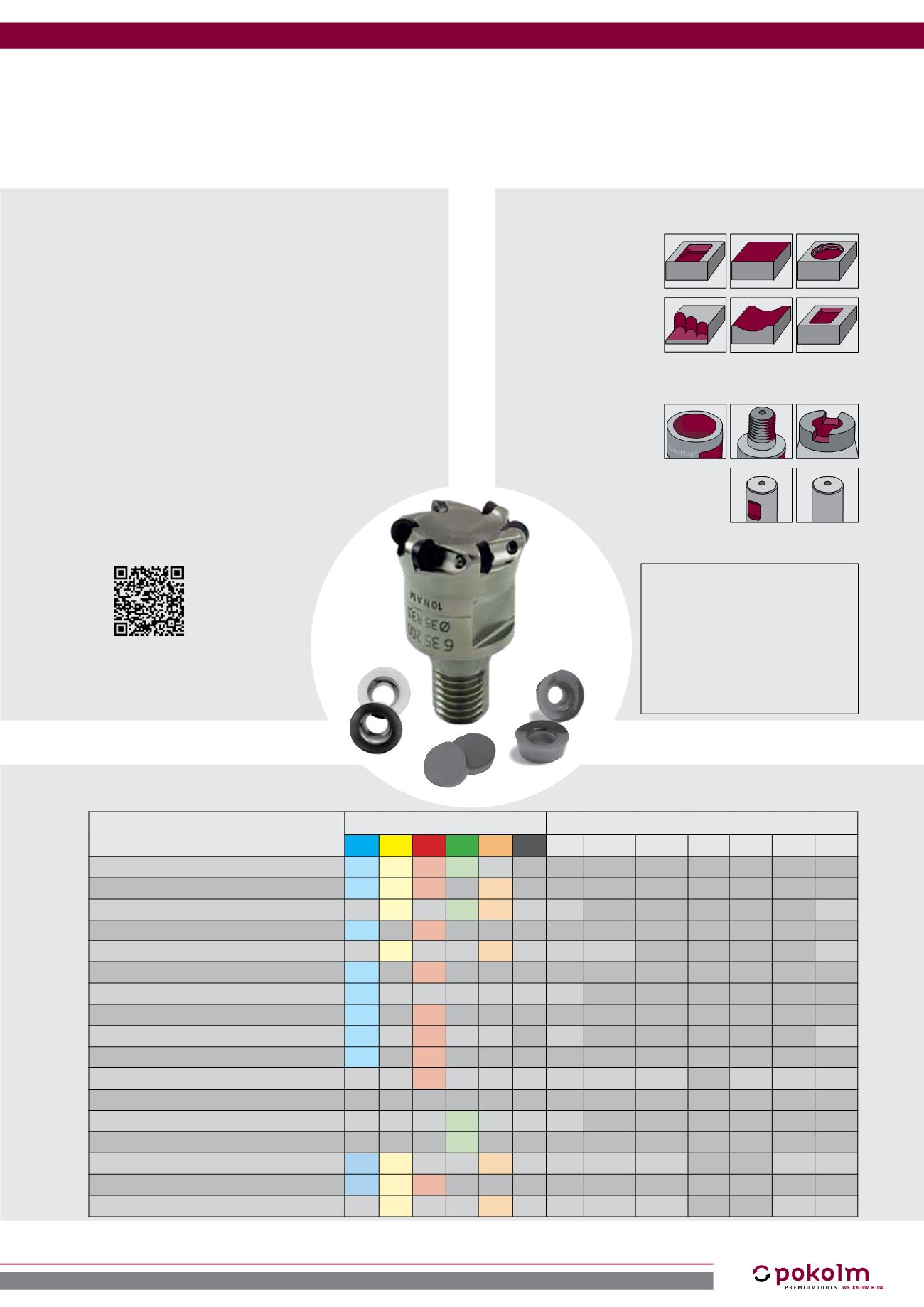

major application

minor application

roughing

pre-finishing

finishing

P M

K

N S

H

5 7 - s1,99 7 - s2,38 10 12 16 20

-

-

-

-

- -

-

-

- -

-

-

-

-

- -

- -

-

-

-

- -

-

-

-

-

-

-

-

-

-

-

-

- -

-

-

-

-

-

- -

-

-

-

- -

-

-

-

-

-

- -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- -

-

-

-

-

- -

-

-

-

-

-

- -

-

-

-

-

-

HSC03 | PPGH

-

-

-

-

-

-

M35 | PCTC

-

-

-

-

Machining types

Connection types

Properties

Cutting materials

Sizes

Page

Practical video

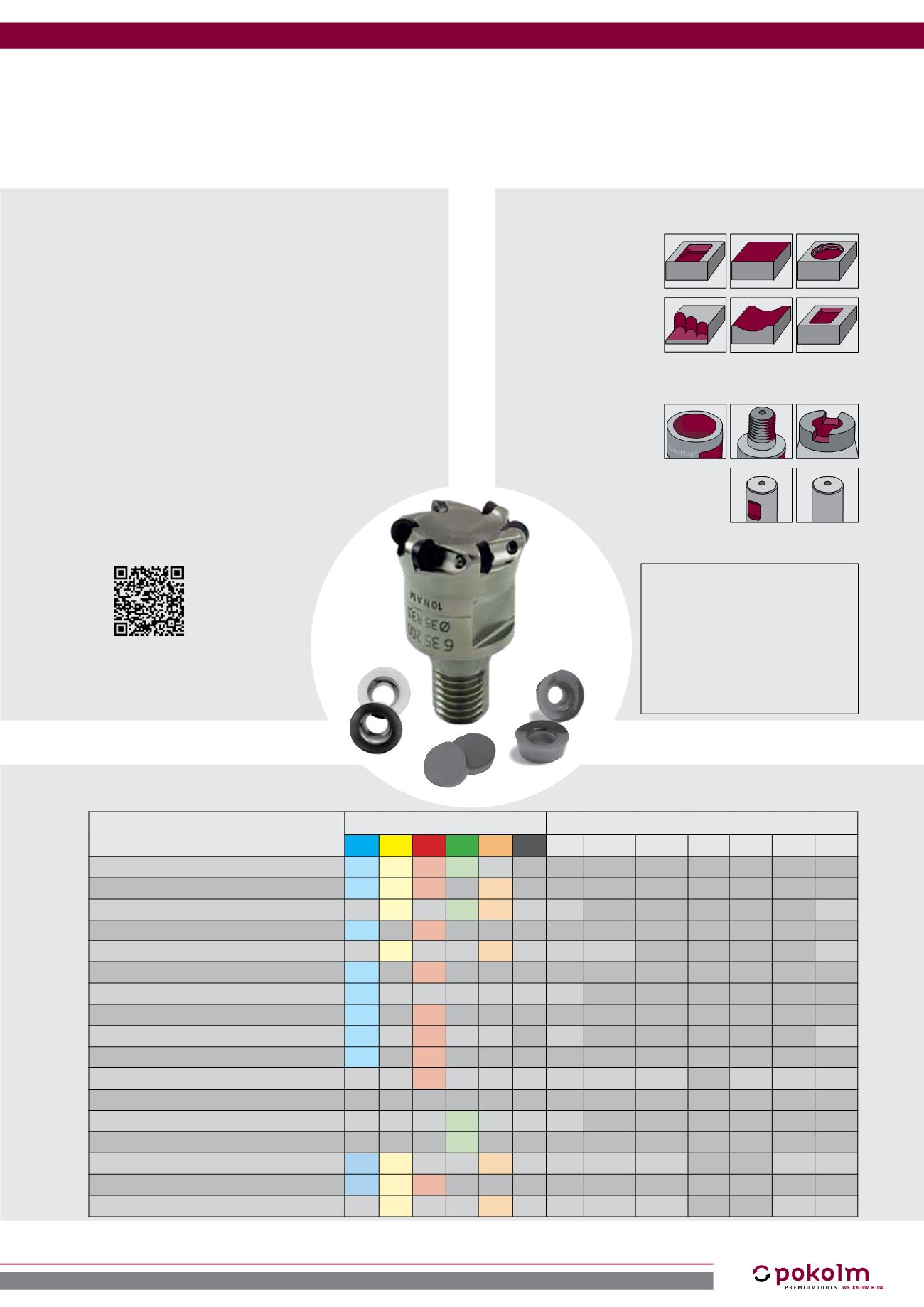

ROUND INSERT CUTTER k0-90°

COPYING CUTTER

the universal geniuses for all standard jobs and the most unusual tasks

uu

Indexable round insert 02 10 896

in 1.4301 / 304 / X5CrNi18-10

uu

Tool diameter 8 - 160 mm

uu

0° axial angle for maximum contour accuracy

uu

in conjunction with

DUOPLUG

®

maximum stability

uu

7° axial angle ensures low power consumption

uu

Stable toolholder due to embedded indexable inserts

uu

8 different hard metal qualities with 9 adapted

high-performance coatings

Carbide grade | coating

K10 | PVTi (RDHX - concave moulding)

P40 | PVTi

P40 | PVML

K10 | polished

HSC05 | PVTi; HSC05 | PVFN

P25 | PVGO

P25 | PVTi

P40 | PVGO

CBN C

K10 | PVDiaN

M40 | PVST

K10 | PVTi

P25 | PVSR

P40 | PVSR

CBN S

ISO standard

Insert diam. d (mm) - thickness (s mm)

r2.5 - diam. 8 - 20 mm 76

r3.5 - diam. 12 - 30 mm, s 1.99 78

r3.5 - diam. 15 - 42 mm, s 2.38 81

r5 - diam. 20 - 52 mm 85, 90

r5 - diam. 20 - 35 mm, CBN 95

r6 - diam. 24 - 80 mm 97, 101

r8 - diam. 32 - 160 mm 106, 109

r10 - diam. 40 - 160 mm 113