7

Important: the scope of delivery of each

COOLCAP

®

cooling arbor includes one cap each. When ordering, please

always state whether you want a cap for air/MMS or a cap for emulsion/cooling water. Additional caps can be orde-

red separately. Always tighten and loosen caps only with an application tool or a box wrench!

HSK 100 Form A

for shrinking | CoolCap®

for shrinking |

CoolCap®

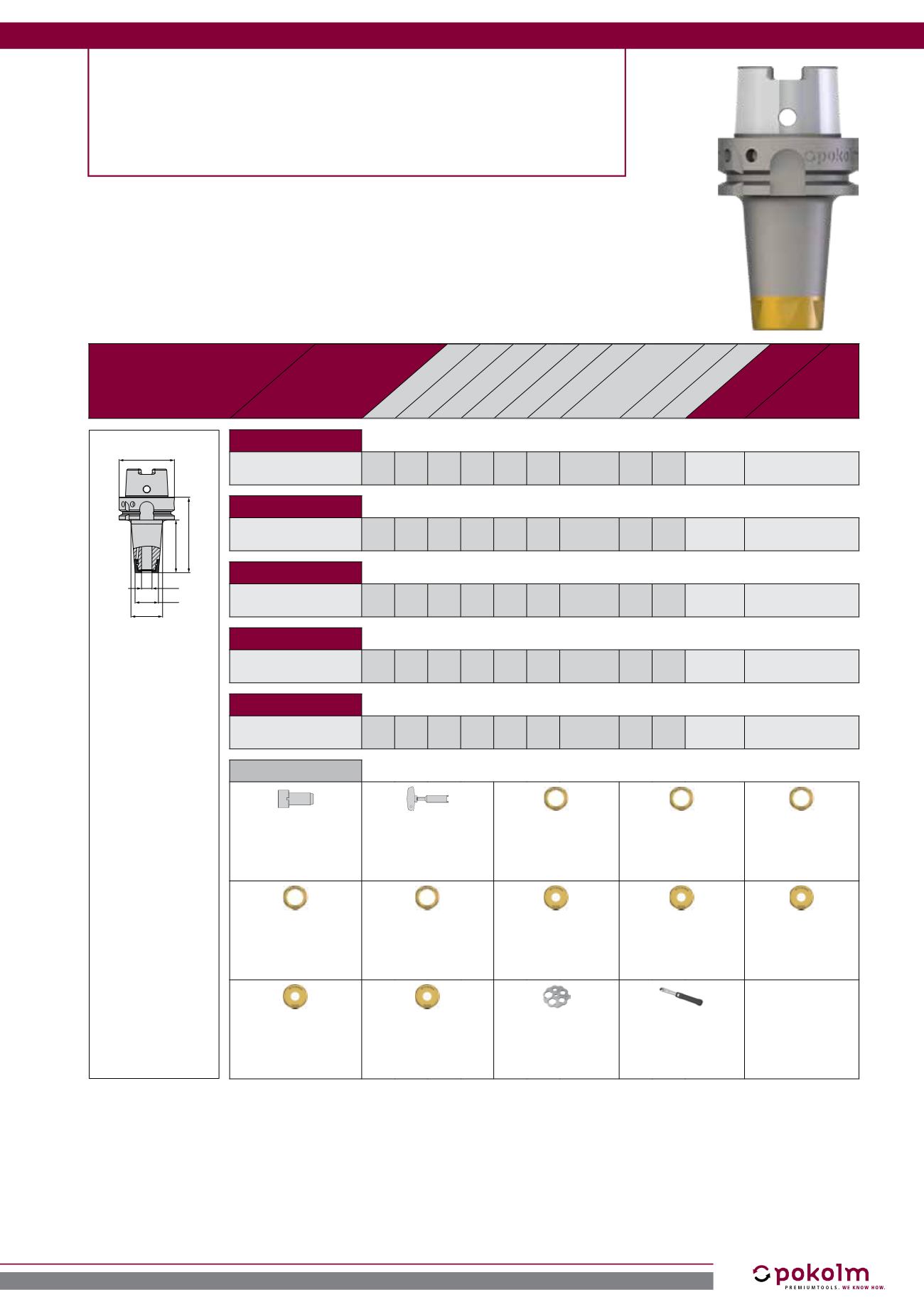

Catalogue no.

Form/DIN

Accessories

Features

d

1

l

3

A d

3

d

4

d

2

l

2

l

1

d

2

l

3

d

3

d

1

d

4

A

for diam. 6

100 06 A100 SR1 diam.

6

100 129 16.5 32.3 HSK

100

form A -

-

A, B, C, H,

M, N

for diam. 8

100 08 A100 SR1 diam.

8

100 129 20.5 36.3 HSK

100

form A -

-

A, B, D, I,

M, N

for diam. 10

100 10 A100 SR1 diam.

10

100 129 22.5 38.3 HSK

100

form A -

-

A, B, E, J,

M, N

for diam. 12

100 12 A100 SR1 diam.

12

100 129 26.5 42.3 HSK

100

form A -

-

A, B, F, K,

M, N

for diam. 16

100 16 A100 SR1 diam.

16

100 129 31.5 47.3 HSK

100

form A -

-

A, B, G, L,

M, N

Accessories

KMR-100A

coolant supply tube for

HSK-tooling

A > Page 12

SCHLUESSELHSK100

spanner for coolant tube

B > Page 12

SR1 S06 SW17

COOLCAP®-Screw-On

Cap for shrinking Ø 6

C > Page 12

SR1 S08 SW21

COOLCAP®-Screw-On

Cap for shrinking Ø 8

D > Page 12

SR1 S10 SW22

COOLCAP®-Screw-

On Cap for shrinking

Ø 10, E > Page 12

SR1 S12 SW27

COOLCAP®-Screw-On

Cap for shrinking Ø 12

F > Page 12

SR1 S16 SW32

COOLCAP®-Screw-On

Cap for shrinking Ø 16

G > Page 12

SR1 A06 SW17

COOLCAP®-Screw-On

Cap for shrinking Ø 6

H > Page 12

SR1 A08 SW21

COOLCAP®-Screw-On

Cap for shrinking Ø 8

I > Page 12

SR1 A10 SW22

COOLCAP®-Screw-

On Cap for shrinking

Ø 10, J > Page 12

SR1 A12 SW27

COOLCAP®-Screw-On

Cap for shrinking Ø 12

K > Page 12

SR1 A16 SW32

COOLCAP®-Screw-On

Cap for shrinking Ø 16

L > Page 12

SR1 ZSW 001

COOLCAP®-applying

tool

M > Page 13

DMS 3/8 8-60 NM

torque wrench 3/8“

N > Page 13

• Hollow taper shank arbors according to DIN69893 form A, maximum precision

• fine balanced to G 6.3 gmm at 12,000 rpm

• with internal coolant supply and bore hole for the coolant supply tube

• effective direct cooling for solid carbide end mills because of a ring-shaped

cooling jet

• increased process reliability when using milling cutter bodies with indexable

inserts in connection with extensions by removing the chips from the cutting area