Material to be machined: INCONEL 625

Machining time shortened by no less than 40% -

SPINWORX

®

makes it possible.

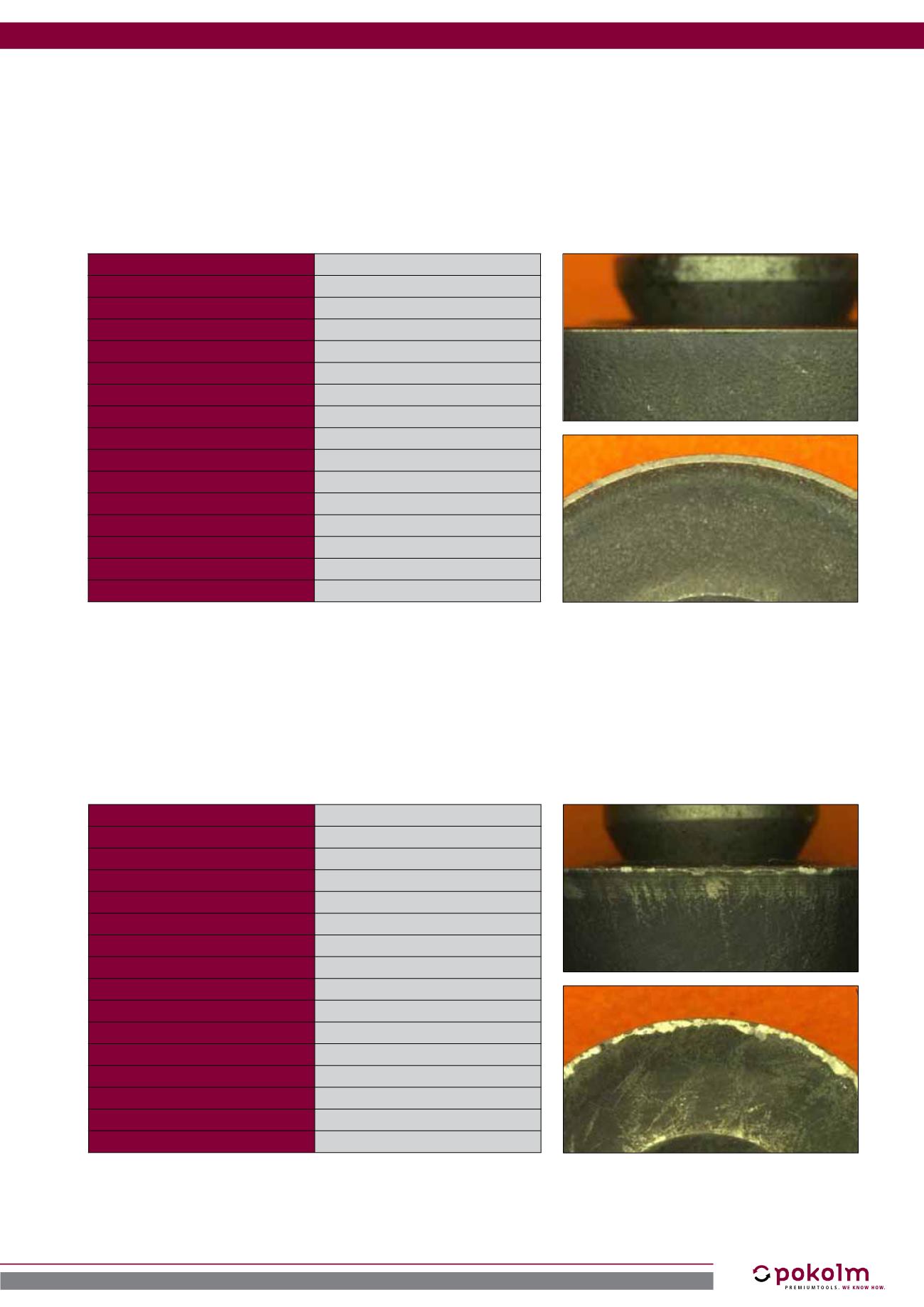

Wear patterns on insert

DR12-8D3

Tool

DR12-052-A22-06

Arbor

50 22 750

Overhang [mm]

102 mm

Cooling

emulsion external

Insert

DR12-8D3

Coating

D

V

c

speed [m/min)

45

V

f

feed rate [mm/min]

570

n(s) [min

-1

]

320

D

c

[mm]

52

f

z

feed per tooth [mm]

0,3

a

p

depth of cut [mm]

1

a

e

width of cut [mm]

40

Tool life [min]

180

Life length [m]

102.6

Stock removal rate [cm

3

/min]

22.8

Material to be machined: 1.0570 / S355J2G3

The focus was on unmanned multi-machine support during these practical tests -

SPINWORX

®

fulfilled all expectations.

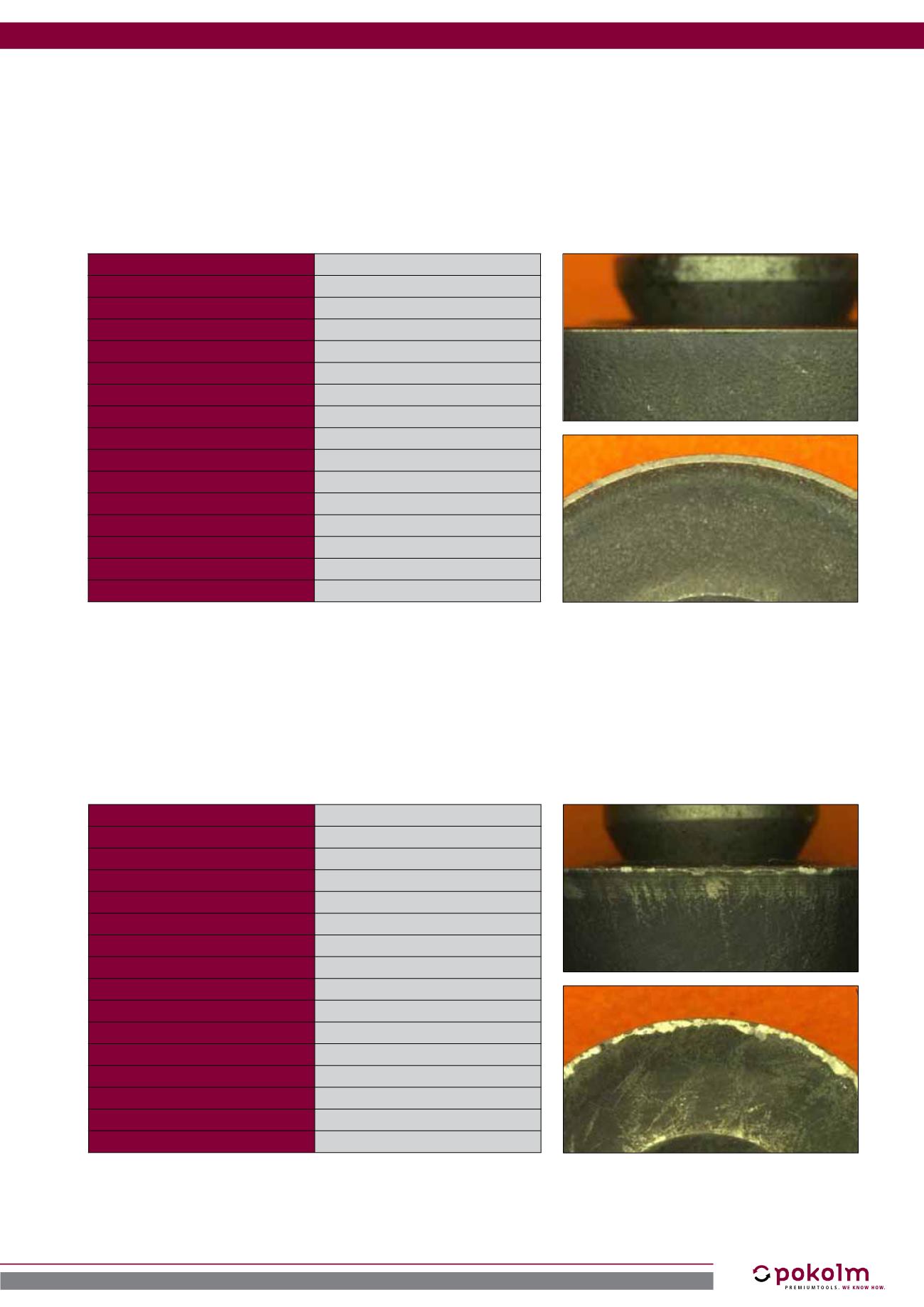

Wear patterns on insert

DR12-8E0

Tool

DR12-052-A22-06

Arbor

50 22 710

Overhang [mm]

102 mm

Cooling

Air ICS

Insert

DR12-8E0

Coating

E

V

c

speed [m/min)

250

V

f

feed rate [mm/min]

4500

n(s) [min

-1

]

1500

D

c

[mm]

52

f

z

feed per tooth [mm]

0.5

a

p

depth of cut [mm]

0.5

a

e

width of cut [mm]

26

Tool life [min]

470

Life length [m]

2115

Stock removal rate [cm

3

/min]

58.5

SPINWORX

®

IN PRACTICAL TESTS –

CONVINCING RESULTS

17