Material to be machined: 1.2083 / X42Cr13

Process-reliable dry machining of a corrosion-resistant plastic mould steel with a tool life of 1429 m without machine downtime

or auxiliary process times - no problem with

SPINWORX

®

.

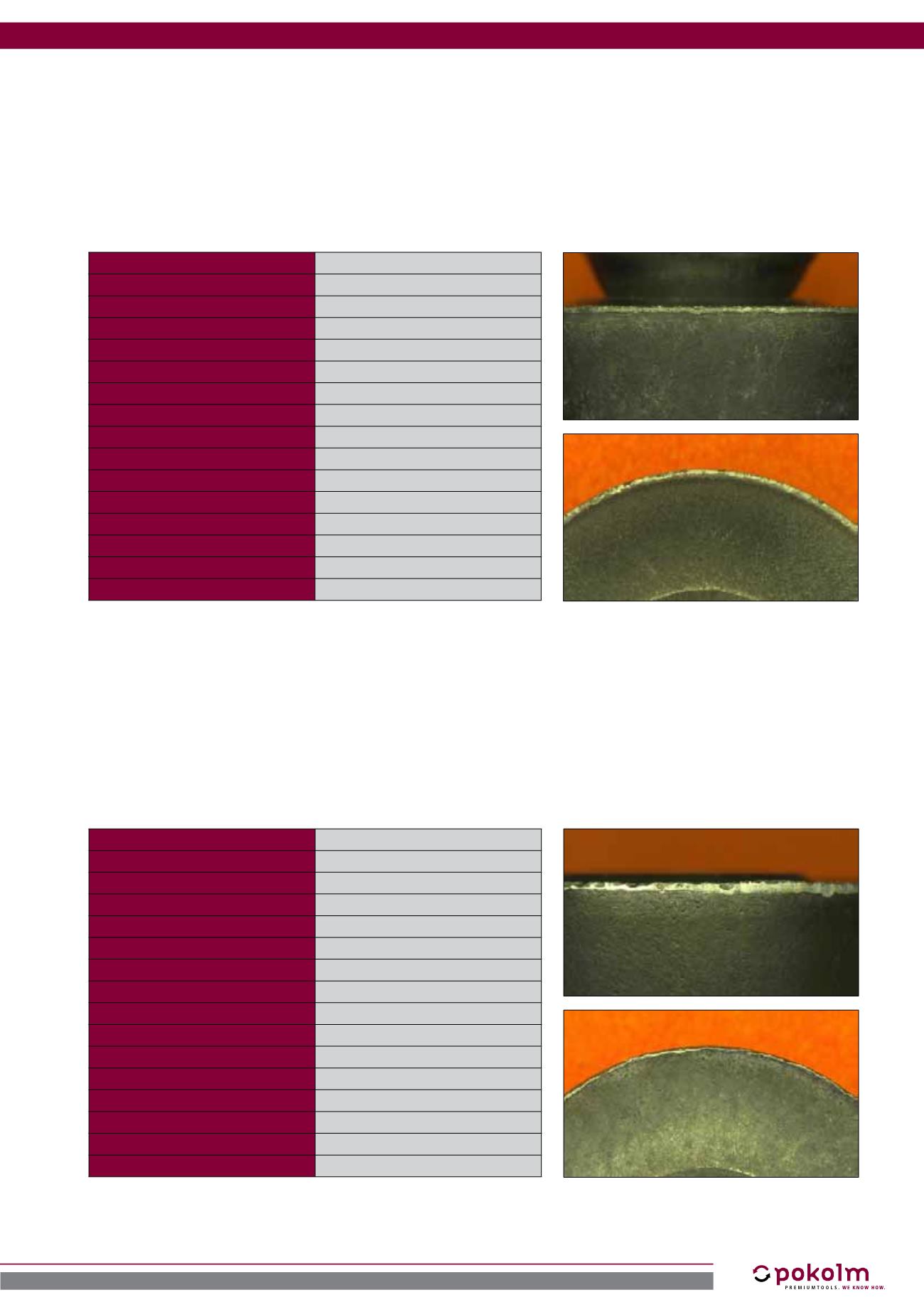

Wear patterns on insert

DR10-8A1

Tool

DR10-035-E16-05

Arbor

50 16 750

Overhang [mm]

83 mm

Cooling

Air ICS & external

Insert

DR10-8A1

Coating

A

V

c

speed [m/min]

180

V

f

feed rate [mm/min]

3970

n(s) [min

-1

]

1819

D

c

[mm]

35

f

z

feed per tooth [mm]

0.436

a

p

depth of cut [mm]

0.35

a

e

width of cut [mm]

20

Tool life [min]

360

Life length [m]

1429.2

Stock removal rate [cm

3

/min]

27.79

Material to be machined: TiAI6V4

Uninterrupted machine running time of 105 minutes with unstable component clamping. This process reliability without any

cutting edge break-out speaks for itself and for

SPINWORX

®

.

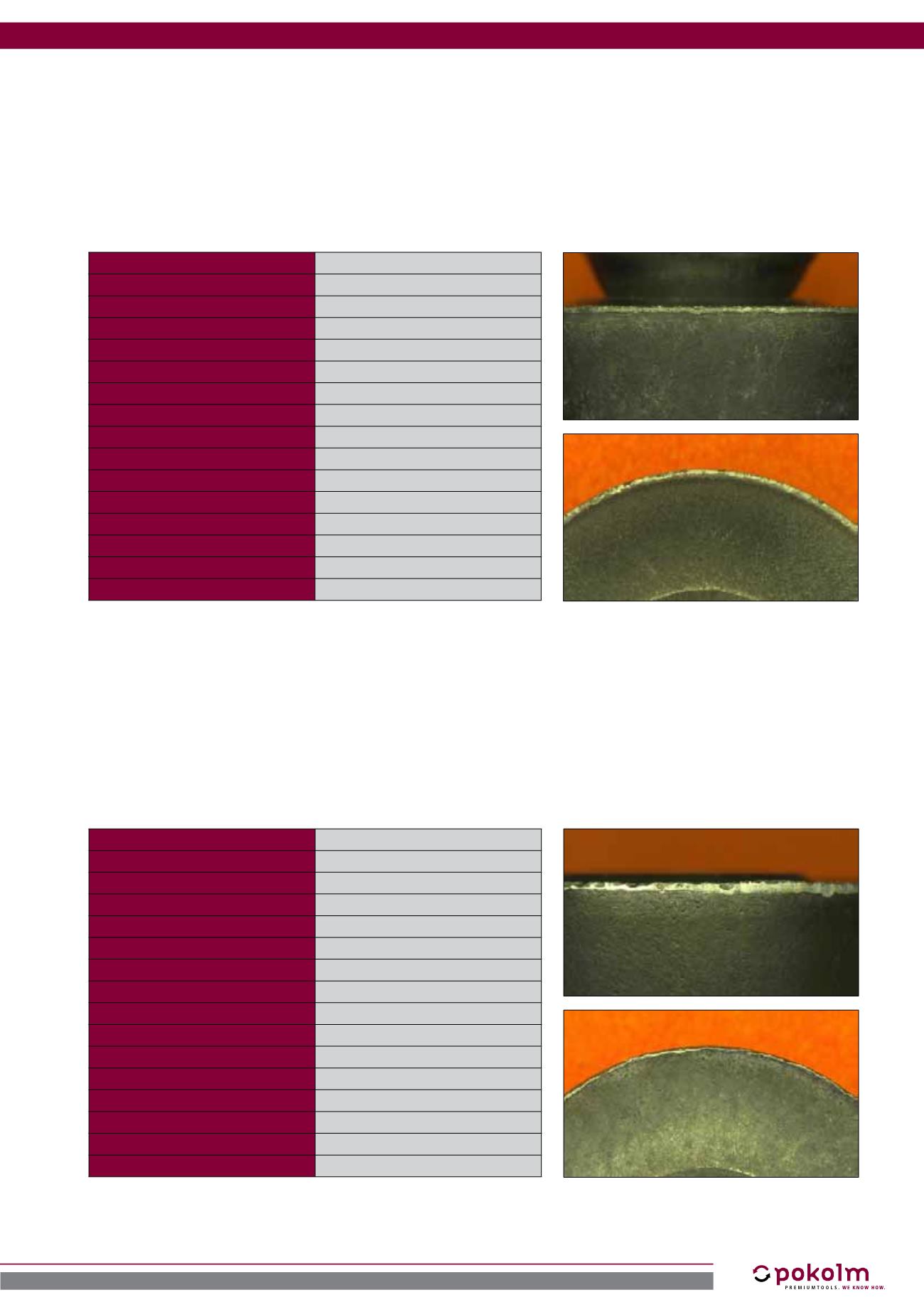

Wear patterns on insert

DR10-8D3

SPINWORX

®

IN PRACTICAL TESTS –

CONVINCING RESULTS

Tool

DR10-025-E12-03

Arbor

50 12 A63

Overhang [mm]

83 mm

Cooling

air emulsion

Insert

DR10-8D3

Coating

D

V

c

speed [m/min]

80

V

f

feed rate [mm/min]

610

n(s) [min

-1

]

1018

D

c

[mm]

25

f

z

feed per tooth [mm]

0.2

a

p

depth of cut [mm]

1

a

e

width of cut [mm]

15

Tool life [min]

105

Life length [m]

64.05

Stock removal rate [cm

3

/min]

9,17

13