Material to be machined: TiAI6V4

Process-reliable machining of titanium alloy for the aerospace industry. Compared to a competitors product and thanks to

SPIN-

WORX

®

it was possible to manufacture a more than three times higher quantity with only one set of inserts. And the inserts wear

limit was not yet reached.

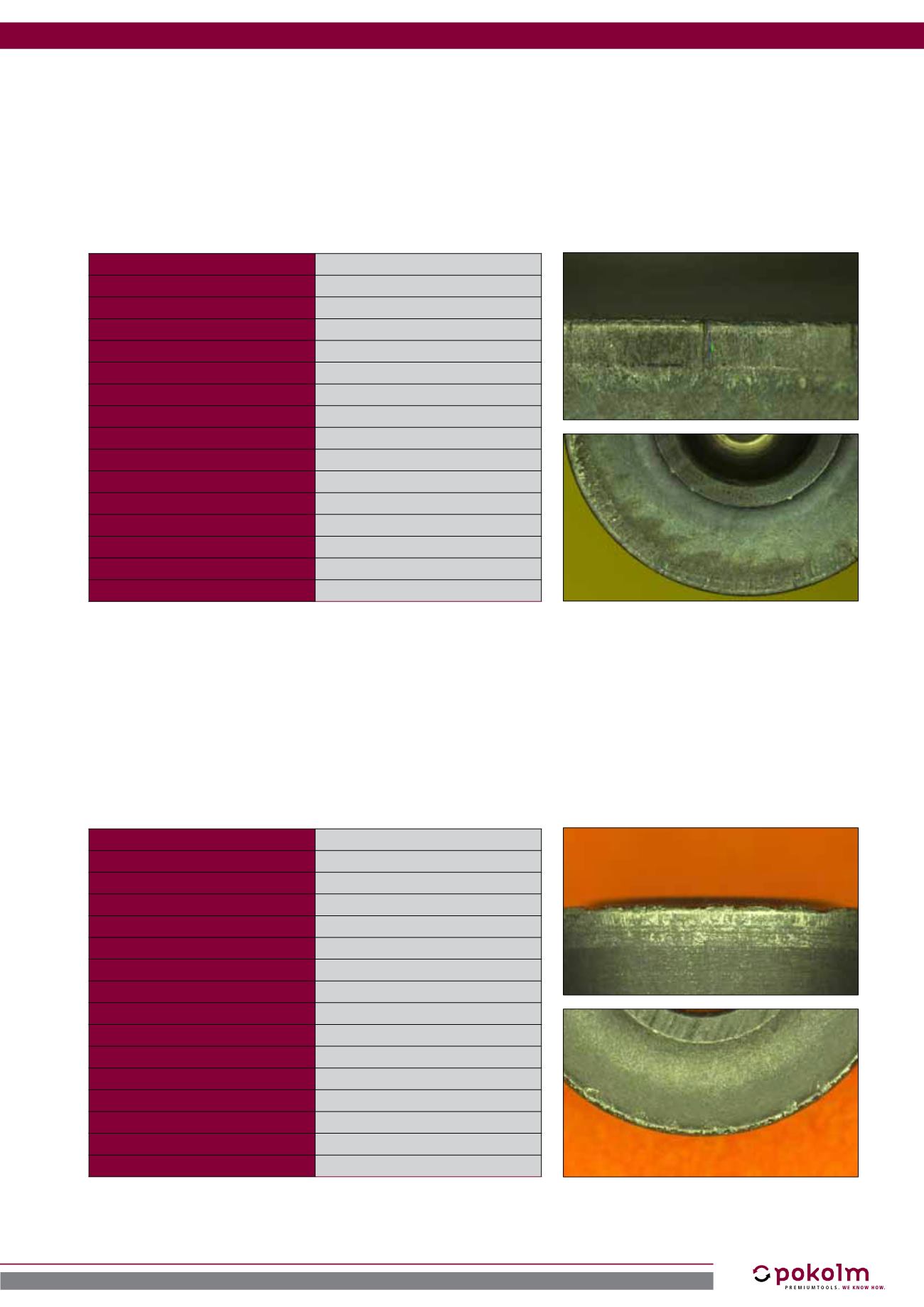

Wear patterns on insert

DR07-8D3

Tool

DR07-025-E12-06

Arbor

50 12 710

Overhang [mm]

80

Cooling

Emulsion

Insert

DR07-8D3

Coating

D

V

c

speed [m/min]

70

V

f

feed rate [mm/min]

810

n(s) [min

-1

]

900

D

c

[mm]

25

f

z

feed per tooth [mm]

0.15

a

p

depth of cut [mm]

1.0

a

e

width of cut [mm]

7.5

Tool life [min]

440

Life length [m]

356

Stock removal rate [cm

3

/min]

12

Material to be machined: 1.2312

Uninterrupted machine running time of 579 minutes - and the inserts wear limit was not yet reached. This process reliability

without any cutting edge break-out speaks for itself and for

SPINWORX

®

.

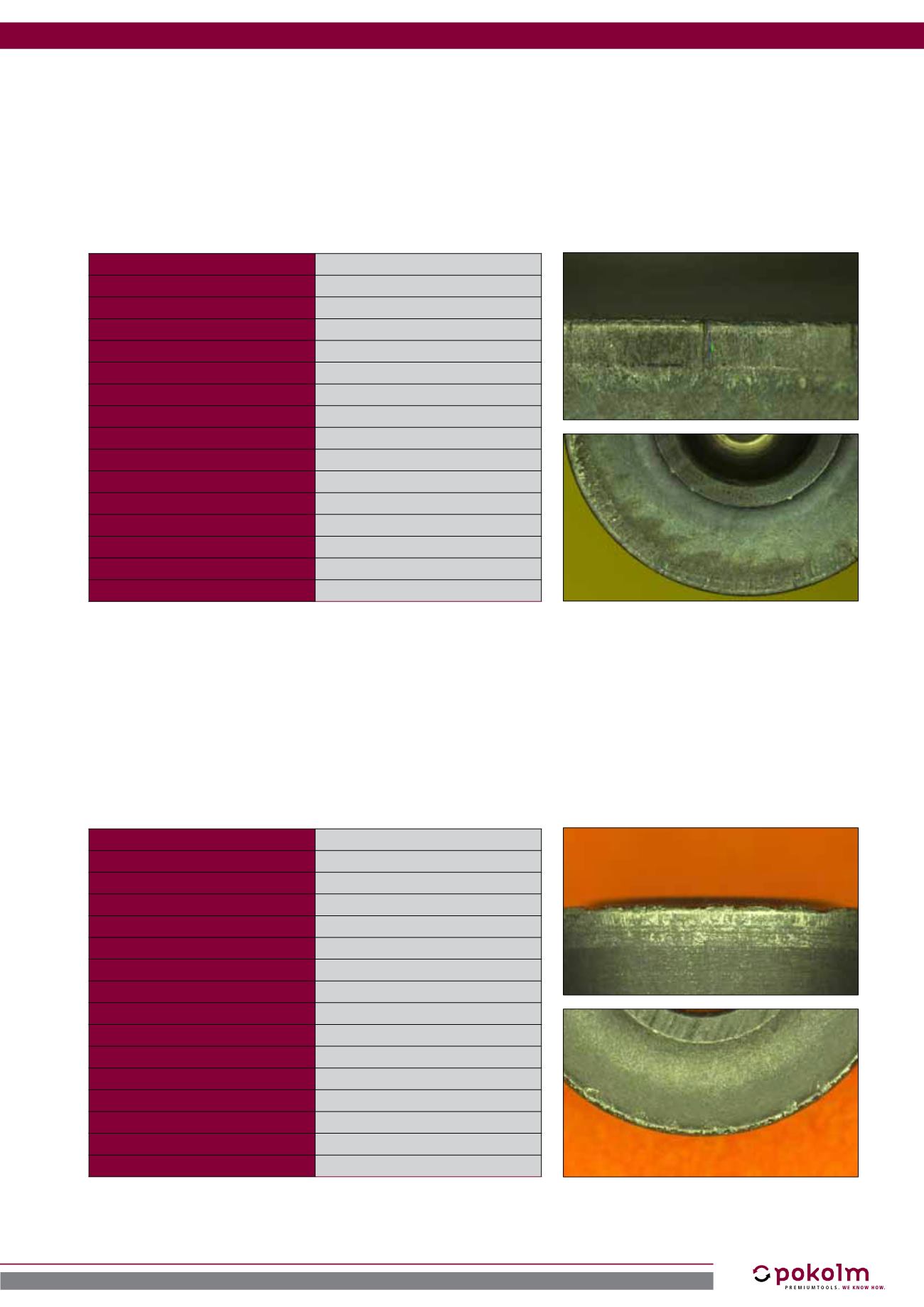

Wear patterns on insert

DR07-8E0

SPINWORX

®

IN PRACTICAL TESTS –

CONVINCING RESULTS

Tool

DR07-025-E12-06

Arbor

50 12 710

Overhang [mm]

90 mm

Cooling

air

Insert

DR07-8E0

Coating

E

V

c

speed [m/min]

200

V

f

feed rate [mm/min]

9150

n(s) [min

-1

]

2545

D

c

[mm]

25

f

z

feed per tooth [mm]

0.6

a

p

depth of cut [mm]

0.6

a

e

width of cut [mm]

15.5

Tool life [min]

579

Life length [m]

5298

Stock removal rate [cm

3

/min]

85

9