GOES ON AND ON AND ON ...

THE SELF-ROTATING INSERT

A

crucial component in the

SPINWORX

®

tooling system are

the self-rotating inserts, which have been optimally mat-

ched to the milling cutter seats of course. And it‘s the special

design features which make safe and long-term function pos-

sible here, too. There are cutting materials with and without

chip groove and different cutting edge geometries available.

Every single insert is delivered with an exactly matching pin.

Order number key:

Example::

DR 10 - 8 A 0

Tool type

Insert size

[diam. mm]

Identification feature

Carbide and

coating code

Geometry and tolerance class

A - Universal type

C - Hard machining

D - Stainless steel /

high-temperature alloys

E - Universal type (new)

DR - SPINWORX

®

0 - sintered without chip groove

1 - sintered with chip groove

2 - ground without chip groove

3 - ground with chip groove

All

SPINWORX

®

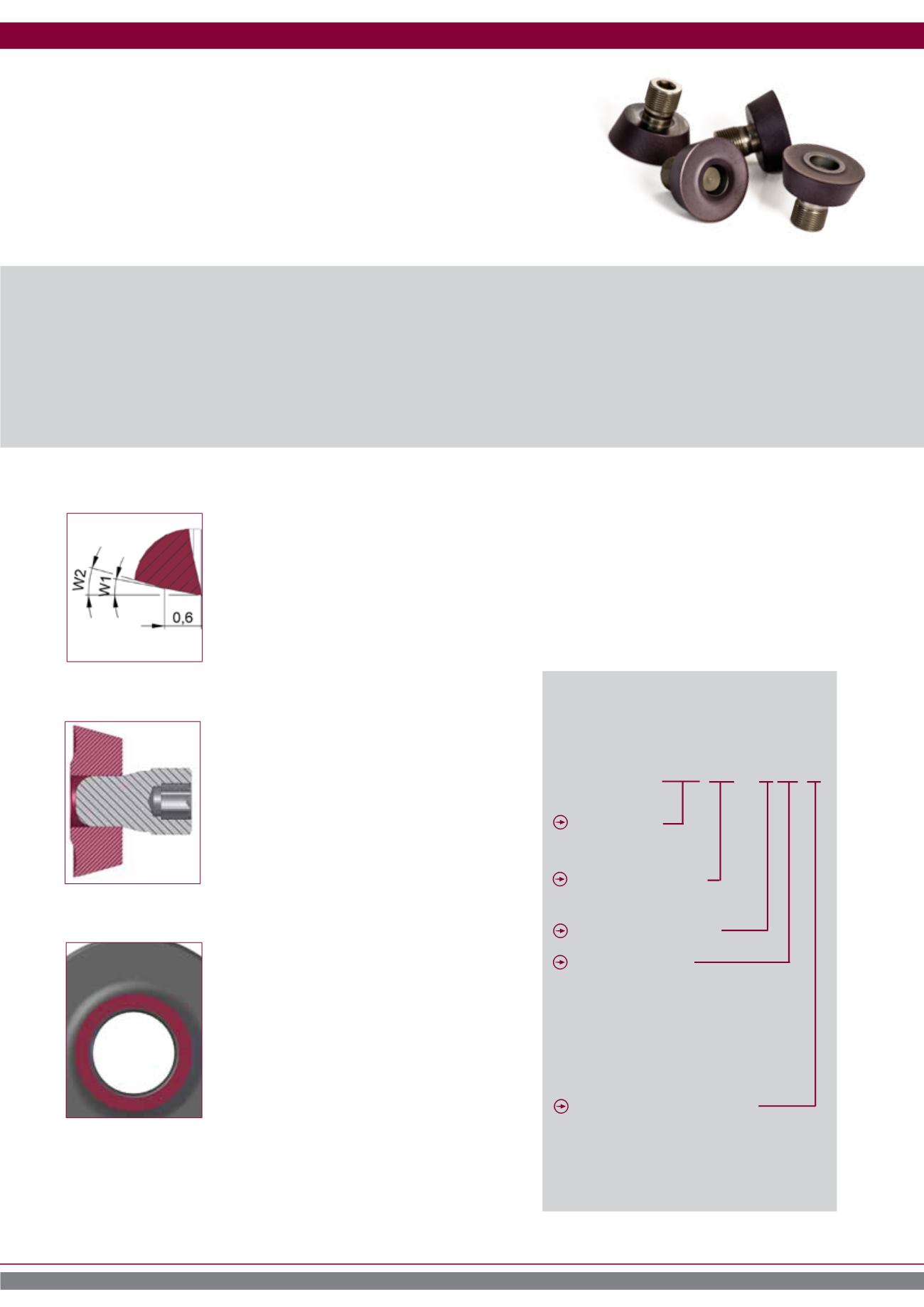

inserts are always equipped

with a race. This protects from non-constant

rotation by forming built-up edges and supports

the characteristics of the embedded insert seat.

The race

Every insert is delivered with a perfectly mat-

ching pin. The cylindrical contact surface of the

insert has an exactly defined percentage contact

area. The cylindrical part of the pin, which provi-

des additional support in the seat of the tool, is

exactly matched to this.

The pin/insert combination

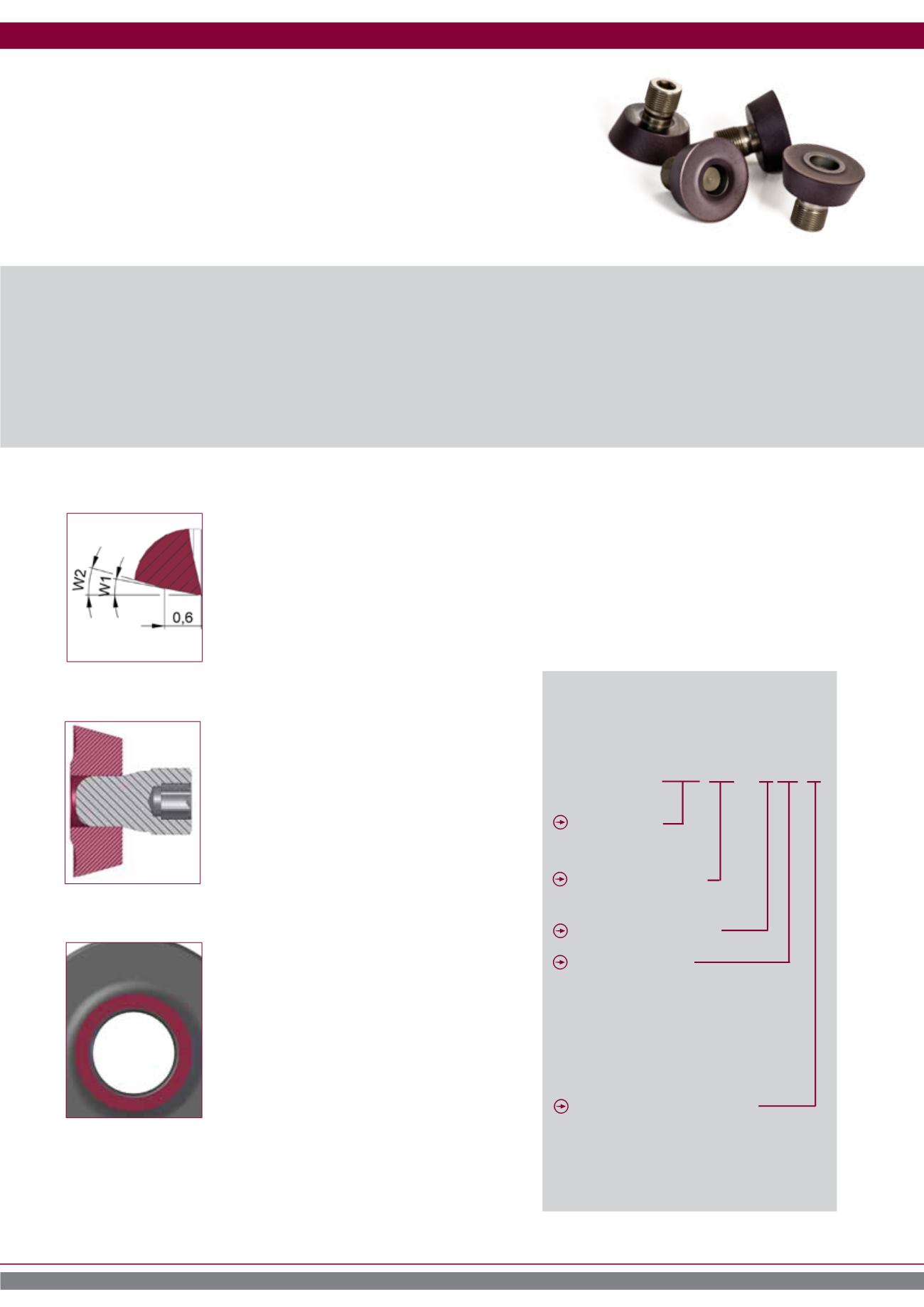

The inserts specifically developed for the

SPINWORX

®

system have a special cutting edge geometry.

The clearance angle W1 reinforces the cutting wedge while the clearance angle W2 provides suffi-

cient space for the cooling media. In addition, they stabilise the cutting edge and form the limiting

feature for the wear mark.

The geometry of the insert

4

spinworx

®

Copy milling cutters milling cutter bodies