Z 00043

T6-0,5NM

T10-1,4NM

T20-2,5NM

Simple assignment of tool and insert

Example:

DR 10 - 025-E12-03

DR 10 - 8E0

Prefixing group key for

the fast assignment of

tool type and insert

Insert size can be recog-

nised directly, straight-

forward assignment

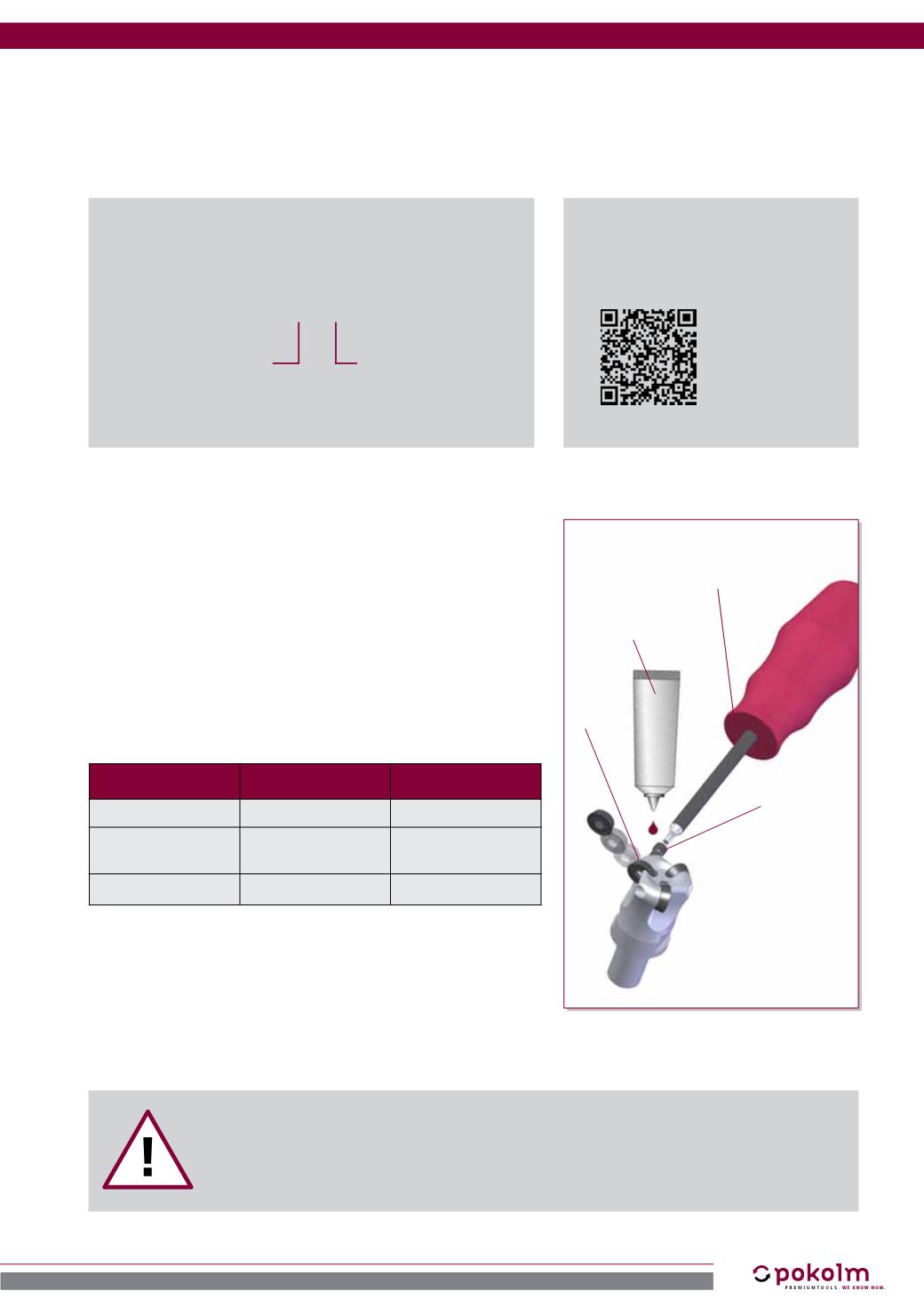

Simple fitting of the inserts in the tool

Step 1:

Place the inserts (1) into the seat provided. Apply the paste included (4)

to the thread of the pin (2) and make sure no paste (catalogue number

„Z 00043“) gets onto the contact surface. Remove any surplus before using

the tool.

Step 2:

Insert the pin (2) into the screw attachment from behind and use the torque

key to tighten according to the specified tightening torque.

Torque key (3)

Pin (2)

Insert (1)

Simple handling thanks to convenient tool

We recommend our torque keys with pre-set tightening torque as a conve-

nient and safe alternative to conventional Torx or torque keys.

Paste (4)

CAUTION! PLEASE NOTE!

For optimum results with the

SPINWORX

®

-tooling system we recommend using internal coolant supply

air, emulsion or MQL for chip removal in the tool! Wet machining up to max speed V

c

of 140 m/min!

Tightening torques

Tool:

Insert:

Practical Video

Spinworx

®

in 1.2738:

Tool life13 hours,

P20 / 40CrMnNiMo8-6-4

DR07-8...

T6

0.5 Nm

DR10-8...

DR12-8...

T10

1.4 Nm

DR16-8...

T20

2.5 Nm

Insert

Torx size

Tightening torque

5